GENERAL SECTOR PERFORMANCE

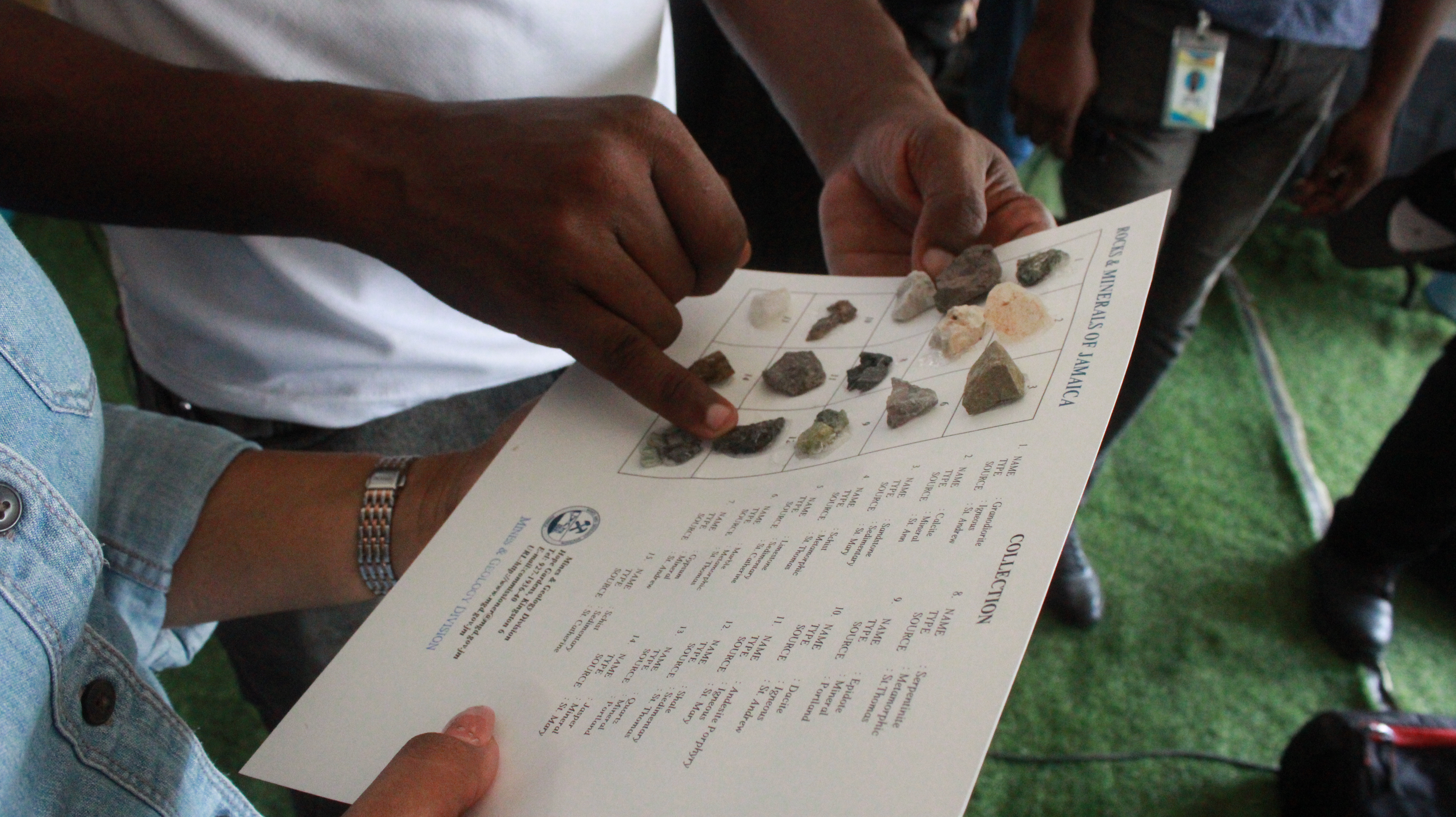

Jamaica’s mineral portfolio is dominated by the production of the metallic mineral, bauxite used for alumina production, and to a lesser extent, non-metallic minerals used in the Construction Sector, and

some industrial applications (Table 1).

The Mining (and Quarrying) Sector contributed 1.8% to Jamaica’s Gross Domestic Product (GDP) in 2023: a slight increase from the 1% in 2022, but lower than the 2.4% in 2019. The Sector is the lowest performer of the Goods Producing Sectors which was led in much greater numbers by Manufacturing, Agriculture and Construction, respectively. Despite this, the Bauxite and Alumina sub-sector still dominates in Traditional Exports, as it has done for decades, particularly over agricultural produce. The sub-sector contributed US$551.5 Million in export earnings in 2023; 68% more than it had in 2022, and 32.3% less than 2019 when the contribution was US$814.2 Million (PIOJ, 2021 and 2024). The Mining Sector has the potential to contribute significantly more to the Jamaican economy.

MINERAL PRODUCTION

Bauxite and Alumina: Bauxite is the only metallic mineral currently mined in Jamaica. Approximately 5.99 million tonnes (Mt) were produced in 2023, of which 34% was processed as crude bauxite, and exported from the Discovery Bay mines mostly to the USA, with a small amount (about 80 thousand tonnes; Kt) to China. The difference of bauxite was converted to 1.4 Mt of alumina at the JAMALCO and WINDALCO (Ewarton) alumina plants. The two alumina plants shipped approximately 1.35 Mt of alumina to various global destinations with JAMALCO accounting for 65% of the exports. Between the companies the alumina was exported to Russia (30%), Latvia (21%), Iceland (20%) and Netherlands (10%) mostly for use as smelter grade alumina from which aluminium metal is made. Smaller amounts were also sent to Libya, Ireland, Ghana and Georgia. Approximately 74.8 Kt of the alumina produced was exported as alumina hydrate to the USA, Panama and Netherlands for use as specialty alumina in non-metallurgical and chemical industrial purposes.

Limestone: This commodity is largely consumed in the Construction Sector where it is crushed to make hard rock aggregate (i.e., for manufactured sand and gravel) and also burnt in making Ordinary Portland Cement (OPC) and industrial lime. Limestone production amounted to 1.9 Mt in 2023; a significant decrease from previous years.

Whiting (Ground Calcium Carbonate): This specialty mineral is prepared from limestone having high purity (more than 96% calcium carbonate) and is used in paints, plastics, animal feed, food and

pharmaceuticals. The production of Whiting showed a sharp increase of 245 Kt in 2023 compared to previous years. This is the highest production over the last decade. It reflects the demand locally, and the increased amounts exported to the USA where one St. Ann-based producer had significantly increased its exports within the western hemisphere (Anonymous 2024).

Marl and Fill: This low-value bulk construction material showed a significant increase in production at 595.4 Kt. The demand for this commodity is driven by the local large infrastructure projects.

Sand and Gravel (River-derived aggregates): The production of river sand and stone was 1.62 Mt tonnes in 2023, a consistent trend from previous years. Demand of this commodity is also driven by the

Construction Sector. This mineral product is a renewable resource, replenished during the wet season.

Other Commodities: Silica Sand, Pozzolan, Gypsum and Shale are the other commodities in the country’s mineral portfolio that were actively extracted, but in relatively small quantities. Silica Sand, used

as an aggregate in thin-set manufacture (for tiling), amounted to 24 Kt, a sharp decrease from the 30 Kt produced in each of the previous years. Pozzolan production increased to 286 Kt from the less than

200 Kt generally produced in previous years. Gypsum production was consistent with previous years. Shale production was unusually low at approximately 59 Kt. Pozzolan, Gypsum and Shale are used in

the manufacture of OPC where the pozzolan is an additive, gypsum is a setting retardant, and shale is a main ingredient burnt with limestone to make clinker, a pre-product before cement.